Ceramic Membranes

Innovative crossflow filtration technology for primary brine refining.

About Ceramic Membranes

What is the Ceramic Membrane?

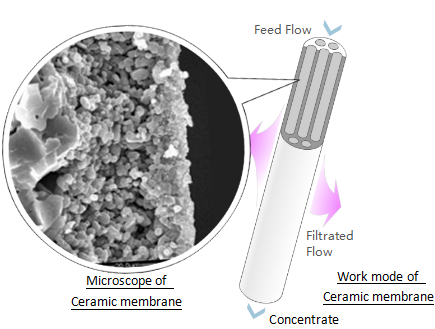

The core of the CRBR system is ceramic membrane, which is made by α-alumina and titanium oxide - High hardness metal oxide. It has a uniformly distributed pore. It rejects the solid content such as calcium hydroxide, calcium carbonate and other particles, giving a qualified purity brine for your resin towers and electrolyzers.

Membrane Module

TFT combines the ceramic membranes in to a metal and use a reasonable structure to collect the permeate - refined brine.

The membrane module is normally made by titanium material to keep it a long working term in the caustic brine environment.

Operating Method of Ceramic Membrane

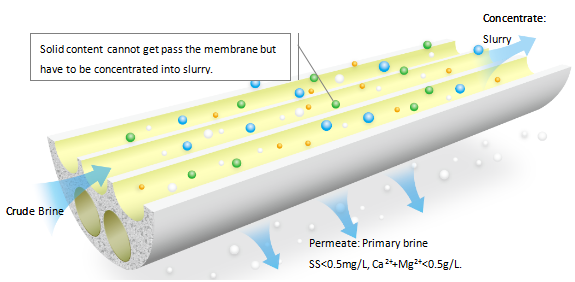

Ceramic membrane is a porous filter with fine pore size which is sintered frome alumina or zirconia, titania oxide under high temperature. It is a ultra filtration membrane, with filter accuracy less than 100 nano-meter. Ceramic membrane always runs at a cross flow filtration mode.

The turbid brine circulates through membrane layer inside single or multi-channel at a high velocity. Driven by trans-membrane pressure, micro-molecule and water passes vertically through the membrane layer to permeation side, the suspended solid and big molecule is rejected in retentate side, thus the raw brine is clarified, purified and concentrated.

Membrane modules Guide

About TANGENT

Tangent Fluid Technology Co., Ltd. (TANGENT) is a producer for ceramic membranes and solution provider for brine purification in chlor-alkali industry. The First-grade CRM ceramic membranes are manufactured under unique technic and strict quality control system. TANGENT has a professional management and technical team with many years of experience in Chlor-Alkali industry. In response to your requirement, TANGENT is willing to offer you high quality membrane products, professional and painstaking technical service in evaluation, design, installation and commissioning. Join us, we will work with you on this innovation technology!

TANGENT FLUID TECHNOLOGY CO., LTD.

Add:No.2-98,Nanjing Pukou Yongning Industrial Park,Jiangsu 211801 China

TEL: +8625 86804049

FAX: +8625 86804046

Web: www.cermem.com, www.tftfluid.com

Email: info@tftfluid.com

Copyright © 2020 Nanjing Tangent Fluid Technology Co., Ltd. ICP 10037821